{{ lang?'快速选择':'Quick select' }}:

据市场研究机构MarketsandMarkets发布的报告显示,2022年全球工业控制与工厂自动化市场规模将达1479亿美元,预计到2027年增长至2188亿美元,期间复合年增长率为8.2%。

当前,世界各国政府推动工业自动化发展的举措越来越多,物联网和人工智能在工业中的应用也日益普及,制造业企业不断追求更高效率和更高生产力等,都成为推动全球工业控制和工厂自动化市场发展的关键因素。

众多因素助力行业发展

1)“工业4.0”助力制造业发展

“工业4.0”是信息物理系统、物联网和云计算的结合,它通过实现远程操作以及实时智能来推动制造业发展。“工业4.0”的实施能够对企业运营效率、生产效率、产品质量、资产利用、供应链管理、工作场所安全和环境可持续性等多个层面进行提升。

目前,石油天然气、食品饮料、化工和汽车等行业纷纷推进“工业4.0”建设,工业控制和工厂自动化市场得以迅速发展。随着“工业4.0”的普及,制造业的大多数流程和系统正在逐步实现自动化,这将使得生产环节未来有可能在零人为错误的情况下全天候运行,减少了总的生产时间,并保证了从原材料采购阶段到开发最终产品过程的质量。这一过程中,企业通过自动化解决方案(如SCADA、HMI、DCS和PLC)来对部署在制造工厂中的机器进行操作和控制。

2)对增强现实(AR)技术的需求上升

近年来,增强现实技术的发展增强了对现实生活情景的感知和呈现。该技术在兼容设备(如智能手机相机、人机界面或智能眼镜)查看的图像上叠加数字信息。这些设备通常由语音控制,佩戴者通过免提交互的方式进行使用。机器学习与基于物理的建模相结合,使工程师能够创建完整的增强现实体验,向工厂的技术人员展示维修车间机器的过程。在工业自动化的构建过程中,企业越来越多地在工厂车间使用增强现实技术来提高生产效率,改善生产流程。

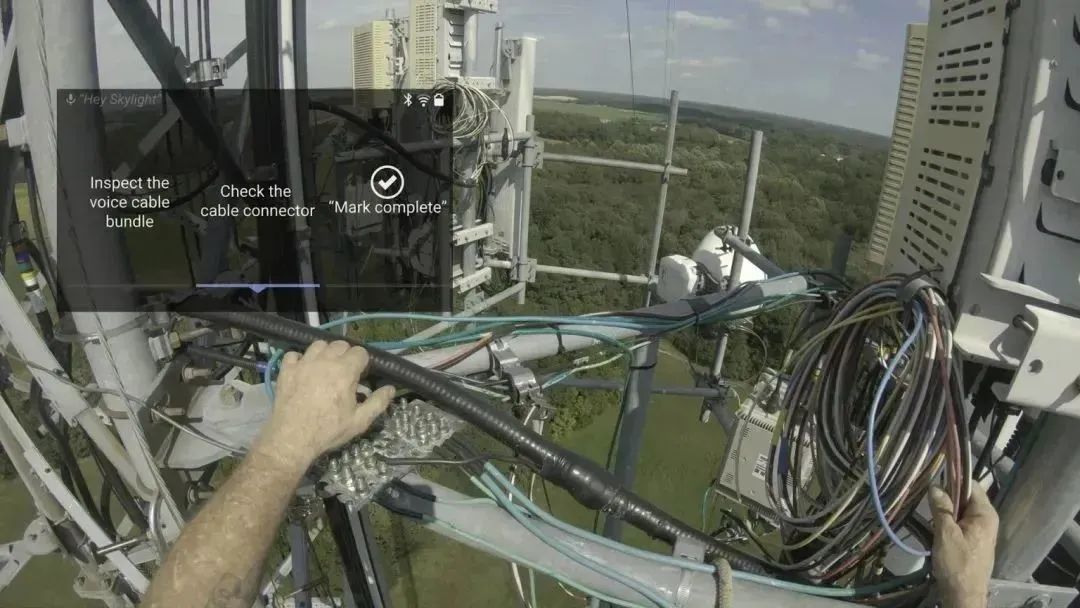

Upskill的Skylight应用( 来源:Upskill)

增强现实技术在工业生产过程中的应用提高了工人的生产力。例如,GE医疗使用了Upskill公司的增强现实工业平台Skylight,该平台将GE医疗的仓库订单任务的完成速度提高了46%。据Upskill统计称,Skylight平台帮助客户将生产力平均提升了32%。

3)政府推动工业自动化发展

与此同时,世界各国政府都在大力支持工业发展,以确保其国家的全面发展,因此许多国家采用了各种自动化和通信技术来推动工业的结构演进。值得一提的是,各国政府也都在关注流程工业和离散工业的扩张。例如,新加坡政府寻求与各种协会进行合作,如新加坡食品制造商协会(SFMA)和食品创新与资源中心(FIRC),在食品和饮料行业采用了诸如SCADA、PLC、DCS、机器人和电缆等最新的自动化解决方案;印度政府的国家制造业政策(NMP)正在推动该国制造业的发展,此外印度政府还采取如“印度制造”计划等一系列措施以鼓励企业实现自动化。

多重挑战如影随形

全球工业控制与工厂自动化市场规模在日益扩大的同时,行业面临的挑战也始终不断,对于其中的参与者而言,了解挑战,才能更好地把握机遇。

1)熟练劳动力短缺

只有熟练的工作人员才能操作工业自动化设备和系统,因为复杂的制造过程可能会被非熟练工作人员误解,从而导致操作失误和故障。熟练工和资金的短缺、合理的自动化配置;易用性问题;技术困难会阻碍工业自动化设备的运行。因此,专业知识的缺乏成为许多行业实现自动化的障碍,这也是工业控制和工厂自动化市场增长面临的主要挑战。

( 来源:Upskill)

2)终端行业的波动

根据英国石油公司发布的《2021年世界能源统计回顾》报告显示,2020年油价平均为41.84美元/桶,是自2004年以来的最低水平。全球石油消耗量创纪录地下降了910万桶/天,降幅为9.3%,创下了2011年以来的最低纪录。美国、整个欧盟(EU)和印度等主要经济体的石油需求都有所下降。全球石油产量缩减了660万桶/天。因此,炼油厂的利用率下降了8个百分点,达到74.1%,创下1985年以来的最低纪录。

此外,中美之间持续的贸易战导致市场上半导体芯片的短缺日益严重,这对包括电子产品在内的各种产品和设备的制造都产生了不利影响。其他重大地缘政治事件,如俄罗斯-乌克兰战争和主要制造中心从中国转移到其他国家等,已经扰乱了整个供应链。

目前,自动化设备和工厂自动化解决方案被广泛用于石油、天然气、半导体和电子等行业的多种应用,包括过程参数的测量,例如压力、液位和油气流量的检测等,全球石油和半导体市场的任何波动都将影响工业控制和工厂自动化市场的增长。

市场的昨天与明天

根据调研数据,MarketsandMarkets对工业控制与工厂自动化市场2022-2027年的发展趋势进行了预测,从中我们可以获得哪些讯息,对未来发展又有怎样的启示?

1)工业传感器市场或将迅速增长

工业传感器领域的增长是由工业4.0和工业物联网(IIoT)的日益普及以及无线传感器市场的扩张所推动的。预测性维护预计将在未来几年为工业传感器市场的参与者提供利润可观的机会,它包括捕获传感器数据,协助数据通信并进行预测等。由于传感器是预测性维护解决方案的重要组成部分,预计未来几年市场对工业传感器的需求将大幅增加。

2)预测期内DCS有望占据最大份额

在预测期内,分布式控制系统(DCS)部分预计将占工业控制和工厂自动化市场的最大份额。该部分的增长得益于新兴经济体的快速工业化。发展中国家电力部门相关的扩张和增容计划将在预测期内推动对DCS的需求。

3)流程行业中石油和天然气领域增长显著

工业控制和工厂自动化技术使石油和天然气行业的运营商能够远程监控设施,并获得有关库存和使用设备的日常状态信息。远程监控能够远程采集设备数据,同时它还降低了风险,提高了劳动力的安全和效率。

4)亚太地区未来可期

2021年,亚太地区的工业控制和工厂自动化市场占据了整个市场的最大份额(35.9%)。该地区市场的增长可归因于工业自动化技术的日益普及,特别是在中国和印度。中国市场的增长源于劳动报酬的提高和大量汽车制造企业的存在。

According to the report released by the market research institute MarketsandMarkets, the global industrial control and factory automation market will reach US $147.9 billion in 2022, and is expected to grow to US $218.8 billion by 2027, with a CAGR of 8.2%.

At present, governments around the world have taken more and more measures to promote the development of industrial automation, the application of the Internet of Things and artificial intelligence in industry has also become increasingly popular, and manufacturing enterprises continue to pursue higher efficiency and productivity, which have become the key factors to promote the development of the global industrial control and factory automation market.

Many factors contribute to the development of the industry

1) "Industry 4.0" helps the development of manufacturing industry

"Industry 4.0" is the combination of information physical systems, the Internet of Things and cloud computing. It promotes the development of manufacturing industry through remote operation and real-time intelligence. The implementation of "Industry 4.0" can improve the operation efficiency, production efficiency, product quality, asset utilization, supply chain management, workplace safety and environmental sustainability of enterprises.

At present, the oil and gas, food and beverage, chemical and automobile industries have promoted the construction of "Industry 4.0", and the industrial control and factory automation market has developed rapidly. With the popularization of "Industry 4.0", most processes and systems in the manufacturing industry are being gradually automated, which will make it possible for the production link to operate 24 hours a day without human error in the future, reducing the total production time, and ensuring the quality of the process from the raw material procurement stage to the development of the final product. In this process, enterprises operate and control the machines deployed in the manufacturing plant through automation solutions (such as SCADA, HMI, DCS and PLC).

2) Increased demand for augmented reality (AR) technology

In recent years, the development of augmented reality technology has enhanced the perception and presentation of real life situations. This technology superimposes digital information on images viewed by compatible devices (such as smart phone cameras, human-computer interfaces or smart glasses). These devices are usually controlled by voice, and the wearer uses them through hands-free interaction. The combination of machine learning and physics-based modeling enables engineers to create a complete augmented reality experience and show the process of repairing workshop machines to factory technicians. In the process of building industrial automation, enterprises are increasingly using augmented reality technology in factory workshops to improve production efficiency and improve production processes.

Skylight application of Upskill (source: Upskill)

The application of augmented reality technology in industrial production has improved the productivity of workers. For example, GE Healthcare uses Skylight, the augmented reality industrial platform of Upskill, which improves the completion speed of GE Healthcare's warehouse order tasks by 46%. According to Upskill statistics, the Skylight platform has helped customers increase their productivity by an average of 32%.

3) The government promotes the development of industrial automation

At the same time, governments around the world are vigorously supporting industrial development to ensure the comprehensive development of their countries, so many countries have adopted various automation and communication technologies to promote the structural evolution of industry. It is worth mentioning that all governments are also paying attention to the expansion of process industry and discrete industry. For example, the Singapore government seeks to cooperate with various associations, such as the Singapore Food Manufacturers Association (SFMA) and the Food Innovation and Resource Center (FIRC), and has adopted the latest automation solutions in the food and beverage industry, such as SCADA, PLC, DCS, robots and cables; The National Manufacturing Policy (NMP) of the Indian government is promoting the development of the country's manufacturing industry. In addition, the Indian government has also taken a series of measures such as the "Made in India" plan to encourage enterprises to realize automation.

Multiple challenges follow

While the scale of the global industrial control and factory automation market is expanding, the industry is always facing challenges. For the participants, understanding the challenges can better grasp the opportunities.

1) Skilled labor shortage

Only skilled workers can operate industrial automation equipment and systems, because complex manufacturing processes may be misunderstood by unskilled workers, resulting in operational errors and failures. Shortage of skilled workers and funds, reasonable automation allocation; Ease of use; Technical difficulties will hinder the operation of industrial automation equipment. Therefore, the lack of professional knowledge has become an obstacle to the realization of automation in many industries, which is also a major challenge to the growth of industrial control and factory automation market.

(Source: Upskill)

2) Volatility in the end industry

According to the 2021 Review of World Energy Statistics released by BP, the average oil price in 2020 is 41.84 US dollars per barrel, which is the lowest level since 2004. Global oil consumption fell by a record 9.1 million barrels per day, or 9.3%, the lowest since 2011. Oil demand in major economies such as the United States, the European Union as a whole (EU) and India has declined. Global oil production decreased by 6.6 million barrels per day. As a result, the utilization rate of the refinery decreased by 8 percentage points to 74.1%, the lowest since 1985.

In addition, the continuous trade war between China and the United States has led to a growing shortage of semiconductor chips in the market, which has had a negative impact on the manufacturing of various products and equipment, including electronic products. Other major geopolitical events, such as the Russian-Ukrainian war and the transfer of major manufacturing centers from China to other countries, have disrupted the entire supply chain.

At present, automation equipment and factory automation solutions are widely used in a variety of applications in oil, natural gas, semiconductor and electronic industries, including the measurement of process parameters, such as pressure, liquid level and oil and gas flow detection. Any fluctuation in the global oil and semiconductor market will affect the growth of the industrial control and factory automation market.

Yesterday and tomorrow of the market

According to the survey data, MarketsandMarkets predicted the development trend of the industrial control and factory automation market from 2022 to 2027. What information can we get from it and what implications for the future development?

1) Industrial sensor market may grow rapidly

The growth of the industrial sensor sector is driven by the increasing popularity of Industry 4.0 and the Industrial Internet of Things (IIoT) and the expansion of the wireless sensor market. Predictive maintenance is expected to provide profitable opportunities for participants in the industrial sensor market in the next few years, including capturing sensor data, assisting in data communication and forecasting. As sensors are an important part of predictive maintenance solutions, the market demand for industrial sensors is expected to increase significantly in the next few years.

2) DCS is expected to occupy the largest share in the forecast period

During the forecast period, the distributed control system (DCS) is expected to account for the largest share of the industrial control and factory automation market. The growth of this part benefited from the rapid industrialization of emerging economies. The expansion and capacity expansion plans related to the power sector in developing countries will promote the demand for DCS in the forecast period.

3) Significant growth in the oil and gas sector in the process industry

Industrial control and factory automation technology enable operators in the oil and gas industry to remotely monitor facilities and obtain daily status information about inventory and equipment used. Remote monitoring can collect equipment data remotely. At the same time, it also reduces risks and improves the safety and efficiency of labor.

4) The future of the Asia-Pacific region can be expected

In 2021, the industrial control and factory automation market in the Asia-Pacific region accounted for the largest share of the entire market (35.9%). The growth of the regional market can be attributed to the increasing popularity of industrial automation technology, especially in China and India. The growth of the Chinese market stems from the improvement of labor remuneration and the existence of a large number of automobile manufacturing enterprises.